Description

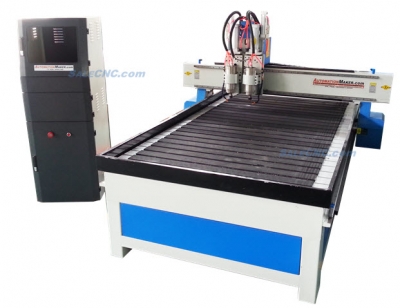

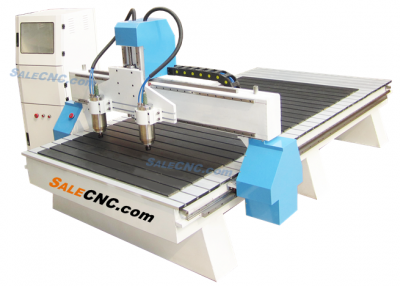

Sale CNC Center YM-6035 with Siemens 808D

When you need the perfect CNC solution for your machine tools, the YM series is your ideal solution.

Machine specification:

Controller with GSK218MC, CNC control system

Sample machine performance: