Description

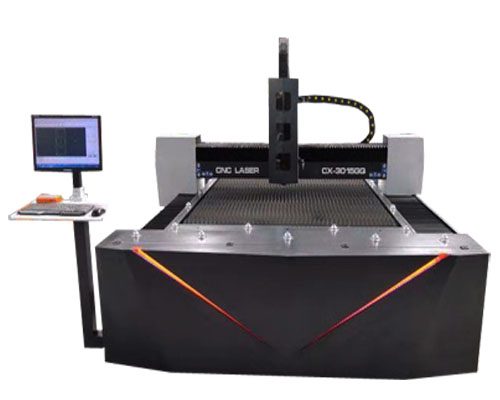

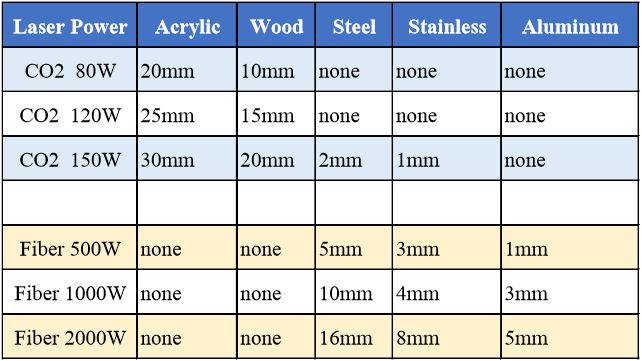

Sell CNC Fiber laser cutting machine FBX16-1530-1000W

Cut steel 14mm, cut stainless 8mm, aluminum 5mm, copper 5mm

| 1000W Laser Cutting Specification | |||||

| Material | Thickness mm | Speed m/min | Pressure (Mpa) | De-Focus | Head Height (mm) |

| Steel O2 | 1 | 17-20 | 1 | 0 | 1 |

| 2 | 6-7 | 0.6-0.8 | +2.5 | 1 | |

| 3 | 3.5-4.5 | 0.4-0.6 | +2.5 | 1 | |

| 4 | 2.5-3 | 0.2-0.4 | +2.5 | 1 | |

| 5 | 1.8-2.3 | 0.2-0.4 | +2.5 | 1 | |

| 6 | 1.2-1.8 | 0.1-0.2 | +2.5 | 1 | |

| 8 | 1-1.2 | 0.1-0.2 | +2.5 | 1 | |

| 10 | 0.7-0.9 | 0.1-0.2 | +2.5 | 1 | |

| 12 | 0.4-0.7 | 0.1-0.2 | +2.5 | 1 | |

| Material | Thickness mm | Speed m/min | Pressure (Mpa) | De-Focus | Head Height (mm) |

| Stainless N2 | 1 | 17-20 | 1 | 0 | 0.6 |

| 2 | 6-7 | 1.5 | -1 | 0.6 | |

| 3 | 2-3 | 1.5 | -2 | 0.6 | |

| 4 | 1-1.5 | 2 | -2 | 0.6 | |

| 5 | 0.5-1 | 2 | -3 | 0.6 | |

| Material | Thickness mm | Speed m/min | Pressure (Mpa) | De-Focus | Head Height (mm) |

| Zinc O2 | 1 | 17-20 | 1 | 0 | 1 |

| 2 | 5-7 | 0.6-0.8 | +2.5 | 1 | |

| 3 | 1.5-1.7 | 0.4-0.6 | +2.5 | 1 | |

| Aluminum N2 | 1 | 8 | 1 | 0 | 0.6 |

| 2 | 4 | 1.3 | -1 | 0.6 | |

| 3 | 1 | 1.3 | -1 | 0.6 | |

| Copper N2 | 1 | 12-14 | 1 | +0.5 | 0.6 |

| 2 | 2 | 1.3 | -0.5 | 0.6 | |

| 3 | 0.5 | 1.3 | -1 | 0.6 | |

| 500W Laser Cutting Specification | |||||

| Material | Thickness mm | Speed m/min | Pressure (Mpa) | De-Focus | Head Height (mm) |

| Steel O2 | 1 | 8-12 | 1 | 0 | 1 |

| 2 | 3-4 | 0.6-0.8 | 0 | 1 | |

| 3 | 1.5-2 | 0.4-0.6 | +2.5 | 1 | |

| 4 | 1.2-1.5 | 0.1-0.2 | +2.5 | 1 | |

| 5 | 1-1.2 | 0.1-0.2 | +2.5 | 1 | |

| Material | Thickness mm | Speed m/min | Pressure (Mpa) | De-Focus | Head Height (mm) |

| Stainless N2 | 1 | 9-12 | 1 | 0 | 0.6 |

| 2 | 2-2.5 | 1.5 | -1 | 0.6 | |

| 3 | 1-1.5 | 1.5 | -1.5 | 0.6 | |

| Zinc O2 | 1 | 7-12 | 1 | 0 | 1 |

| 2 | 2.5-3.5 | 0.6-0.8 | +2.5 | 1 | |

| 3 | 1-1.2 | 0.4-0.6 | +2.5 | 1 | |

If you have any question please contact Sales@salecnc.com

Reviews

There are no reviews yet.