Description

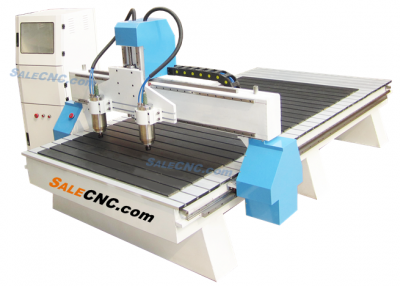

CNC Router Milling รุ่น XJ1325

Sale CNC Router XJ1325

Various designs and Quality carvings.

Specification

- Model: XJ1325

- Working/ Traveling Area: 1,300 x 2,500 x200mm

- Spindle Motor: 3KW-5KW (tool change)

- Motor Drive Precision: Stepping Motor or Servo Motor

- Drive Mechanism: Gear-wheel

- Resolution: 12,000mm/min

- Max Engraving Speed: 12,000mm/min

- Rotating Speed of Spindle: 24,000rpm

- Engraving Tools: Up to 12.00mm

- Frame Cast iron: (Vacuum table)

- Controlling Code Standard G code / M code

- Operating Voltage 1 or 3phase 380v/ 220v

- Software NC Studio or Mach 3, included CAD/CAM software

- Packing size 3.3×2.0×1.8m

- Gross weight 1240kg

machine specification

- Working area (width x length x height) 130 x 250 x 20 cm.

- Spindle Motor 3 kW.

- Stepping Motor Drive or Servo Motor Accuracy.

- Mechanism driven by gear wheel (Gear-wheel).

- Working resolution at 12,000 mm/min.

- Can engrave up to 12,000 mm/min.

- There are tools that can engrave up to 12.00 mm.

- Machine control by G-code and M-code.

- It has a spindle rotation speed of 24,000 rpm.

- Use voltage 1 or 3 phase (380 V / 220 V).

- Machine size (width x length x height) 330 x 200 x 180 cm.

- weight 1,240 kg.

- Various control software such as NC Studio, Mach3 and other CAD/CAM

- There is a program to control holes in square and circle shapes.

- There is a program to control walking and memorize one point at a time (Teaching Mode)

- Can calculate the speed of the material Be it aluminum, thick steel, thin steel, cast iron or brass.

Customers can choose to install Mach3 or NC drivers according to their needs.

example of work

Reviews

There are no reviews yet.